AGENCY SERVICES

Agency Services Overview

WLP Agency’s is a dedicated division which represents as agents or logistical providers for a wide variety of International companies. Some of the companies are incorporated into projects in the projects division and or are stand alone units in their own particular field

Please select a partner company from the left menu.

Click on the button below to contact us:

Griffon Hoverwork

Worldwide leader in the design & manufacture of hovercraft

Griffon Hoverwork Ltd (GHL) is at the forefront of hovercraft development and has been involved in the manufacture and operation of hovercraft since they were first conceived, over 50 years ago. Their customers “fly” Griffon hovercraft in all 5 continents and we support over 200 GHL craft in over 41 countries.

Owned and supported by the Bland Group, the company has achieved strong growth. Griffon relocated their main manufacturing facility from Hythe to Merlin Quay, Southampton UK at the beginning of 2011, in order to increase manufacturing capacity. They now use lean techniques to design and manufacture high quality hovercraft for practical applications.

In the commercial role, Griffon hovercraft are used around the globe for:

Griffon hovercraft are also in use by those responsible for national security and military operations, missions include:

All Griffon Hoverwork hovercraft are designed to meet exacting engineering standards and the larger vessels are often classified to Lloyds Registry standards (or other chosen standards). Their processes and quality management system is certified to ISO 9001; and they are continually developing their approach to provide products with even higher standards of robustness, reliability, availability, performance and with improved value for money.

Griffon take great pride in meeting and exceeding performance criteria. Medium and large craft can operate at speeds in excess of 55 knots but we advise this to be outside of a safe working envelope and therefore specify maximum speeds of 45 knots. The company knows the performance criteria they specify can be achieved; and they can prove this theoretically and through real life application, in over thousands of operating hours.

Griffon Hoverwork design and manufacture hovercraft of varying payloads and application requirements. All craft can be offered in differing configurations to suit requirements, from passenger craft to open well decked cargo carrying craft. The companies extensive skills allow them to manufacture an array of vessels from wind farm support vessels to similar high speed craft – this is further underlined by our Griffon-Cougar ultra fast products.

Multi Flexi Fuel Micro Turbine Generators

The worldwide growing need to establish fuel sources other than petroleum has led to the development of various new engine technologies, mainly in the car industry. A multi-fuel engine is a fuel-burning device which is designed to burn multiple types of fuel in its operation. A flexi-fuel engine, however, is capable of balancing irregularities in the fuel composition. The Multi-Flexi Fuel Micro-Turbine Power Packs developed by MSE are a unique combination of the two engine types mentioned above. They are capable of using various fuel types as well as adjusting to fluctuations in the fuel composition.

The special air injection system of the micro-turbine pressurizes the otherwise low pressure system to a level which is sufficient for the engine injection and as there are no moving parts to cause fire sparks, the turbine can even use flare gas directly from natural sources.

The combustion chamber of the Multi-Flexi Fuel Turbine is designed to reach an extremely low NOx emission level, far below any regulation standards, whereas the CO2 emission is of such low temperature that it can actually be reabsorbed by nature. The average efficiency of standard turbines sold on the market today generally reaches approx. 30% and only surpass that number if equipped with a recuperator or water (steam)

injection system. The Multi-Flexi Fuel Turbine exceeds that rate.

With a rapid, ever swelling hunger for energy, the world is moving towards a decentralized power generation led by an increasing demand for flexible, efficient and small-scale solutions. While power generation from natural gas and intermittent renewable sources is on the rise, as well as the demand for recycling of waste oils and other liquid and gaseous fuels becomes a necessity, the use of industrial applications will increase and the competition to offer customers a full range of solutions will intensify. The TM Multi-Flexi Fuel Micro-Turbine Power Pack is the result of many years of intensive R&D work built on vast experience in the field of turbo-jet engines. The main objective was to find a power generator set that can be driven with a wide range of fuel types, liquid as well as gaseous, including synthetic and flare-off gases.

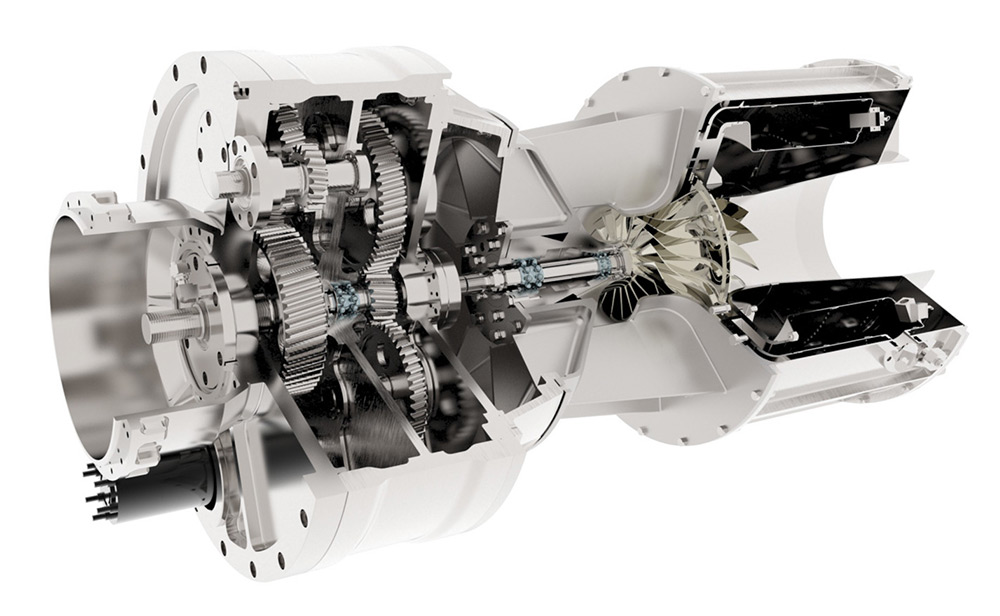

The unit is based on the turbo shaft engine TM-200. The engine consists of a radial compressor, a radial turbine and an annular combustion chamber. The low pressure ratio makes it possible to inject synthetic and flare gases under reasonable pressure. The injectors are designed to handle almost all known fuel types of which numerous have been successfully tested.

Skeldar Drones

UMS SKELDAR, a joint venture between UMS AERO Group and Saab, is Europe’s only provider of both Rotary and Fixed Wing Unmanned Aerial Vehicle (UAV) platforms. With a highly active research and development programme, UMS SKELDAR provides solutions to a wide variety of military defence, civil security and maritime sectors globally. Its current portfolio consists of four vehicles in the 2-12+ hours endurance range. There are two Fixed Wing models including the F-330 and the larger F-720 and two rotary wing models including the SKELDAR V-200 and R-350.

The company is headquartered near Basel in Switzerland, with twin manufacturing facilities in Switzerland (Möhlin) and Sweden (Linköping). UMS SKELDAR is a multi-skilled enterprise with all the capabilities necessary to manage and deliver total UAV programmes. This includes research and development, design, manufacture, testing, training, consultancy, maintenance, Managed Services and finance options.

Alongside design and production, UMS SKELDAR develops its own associated systems which serve to fly various types of UAV’s simultaneously on the same Ground Control Station (GCS). The company can provide customers with qualified ISR instructors for training of unmanned vehicles or to interpret sensor information alongside a RPAS capability requirement. All of the systems provided by UMS SKELDAR utilise exclusive design and build avionics, software and carry an authentic intellectual property rights (IPR).

UMS AERO and Saab have joined forces under a new brand to combine their technology experience. UMS SKELDAR is a multi-skilled enterprise with all the capabilities necessary to manage and deliver total Unmanned Aerial Vehicle (UAV) programmes to a wide variety of military defence, civil security and maritime sectors globally.

Water Witch

Liverpool Water Witch is a 3rd generation family-run business established in 1966, dedicated to building and designing innovative specialist vessels for trash collection, debris removal, aquatic weed control and waterway cleanup operations.

They offer highly versatile road transportable multi-purpose workboats in both steel and aluminium to match waterway operator’s exact requirements and budgets, from lightweight Buddy road-towable debris retrieval and trash skimmer craft, right up to heavy duty workhorses capable of removing up to 1000kg of flotsam at a time and reaching up to 3.65m below water. The Water Witch is similar to a floating bulldozer with a quick-release system for a range of loader attachments to be easily fitted in seconds. Loader attachments available include dredge buckets, log grapples, weed cutters/rippers, access platforms, cranes and more.

Their innovative designs, which include a range of modular waste transfer and storage barges, are backed by nearly 50 year’s hands-on experience working with clients worldwide, based on tried & time-tested designs matched to customer’s exact specification and operational requirements.

Water Witch Workboats are in service in all corners of the world, operating for Ports and Harbours, Marina’s, Irrigation and Environmental Agencies, Not for Profit Organisations and other Agencies.

CTI Producer Water

Oman and most oil producing countries all have a similar problem, Produced Water in Oman for each barrel of Oil produced there are five to seven barrels of Produced Water. Produced Water is the water which comes out of the Oil Water Separators, it contains oil contaminated water but usually it also contains a mix of other toxic and non-toxic elements. This water has two uses, if required it has to be pumped back down to maintain well pressure, for this the trace oil should be removed, the suspended solids also have to be removed to save wear and tear on the pumps that have to pump it back down generally 1,750 meters or more so as not to contaminate the aquafer. If it does not have to be pumped down it has to be de-oiled, and cleaned to a minimum of WHO agricultural standard.

We have three proven technologies to treat this water:

Of them all we prefer to use the CCT as this will generally do most of the work required in an efficient modular way which can be expanded to take as much water as is produced. Also the water can be used for Agriculture or it can be further processed to potable water, water for steam Injection or any other use the client has. If the client has not got a use for the water we can then generate an Agricultural Project that will take all the water.